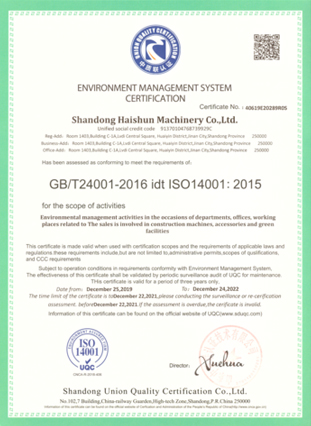

Aiming at the characteristics of complex composition and high mobility of sewage from construction sites, it adopts highly efficient precipitation and physical treatment technology to quickly purify industrial wastewater such as slurry water and ensure that it meets the standards for discharge or recycling. The modularized design of the equipment is highly adaptable to meet the flexible deployment needs of different construction sites, helping green construction and environmental acceptance.

Integrating biodegradation and membrane filtration technology, it can efficiently treat organic matter and solid-liquid separation in domestic wastewater, and the effluent water quality meets the national standard. The equipment operates quietly with low consumption, and supports above ground and buried installation methods, saving space and harmonizing with the surrounding environment, which is an ideal solution for domestic sewage treatment.

It covers concrete mixing building, dry mortar mixing plant, stabilized soil mixing plant and other equipment, as well as the host machine, batching system, conveying system and other supporting equipment. The whole plant adopts intelligent control and wear-resistant technology, which greatly improves production efficiency. The products are suitable for commercial concrete stations, engineering stations and other scenarios, and support customized solutions to ensure accurate concrete proportioning and stable quality, meeting the high standard requirements of large infrastructure and municipal projects.

In response to the dust, residue and other solid waste pollution problems generated during the concrete mixing process, the equipment adopts fog pile, spraying and solid waste separation equipment to effectively inhibit the spread of dust in the work area and solid waste recycling. The equipment integrates automation control module, which is suitable for all kinds of mixing plant working conditions, with both environmental compliance and economic benefits, helping the enterprise to realize the goal of “zero emission” and enhance the image of green production.

Innovative use of PID algorithm and Internet of Things technology, precise control of concrete curing water temperature (± 0.5 ℃), to ensure that the strength of construction in winter and summer up to standard. The system automatically raises and lowers the water temperature, supports remote monitoring and fault warning, and effectively improves the quality stability and construction efficiency of large volume concrete projects.